Adiprene® Ribbon Flow®

Rotational cast prepolymers for fast, efficient roll covering

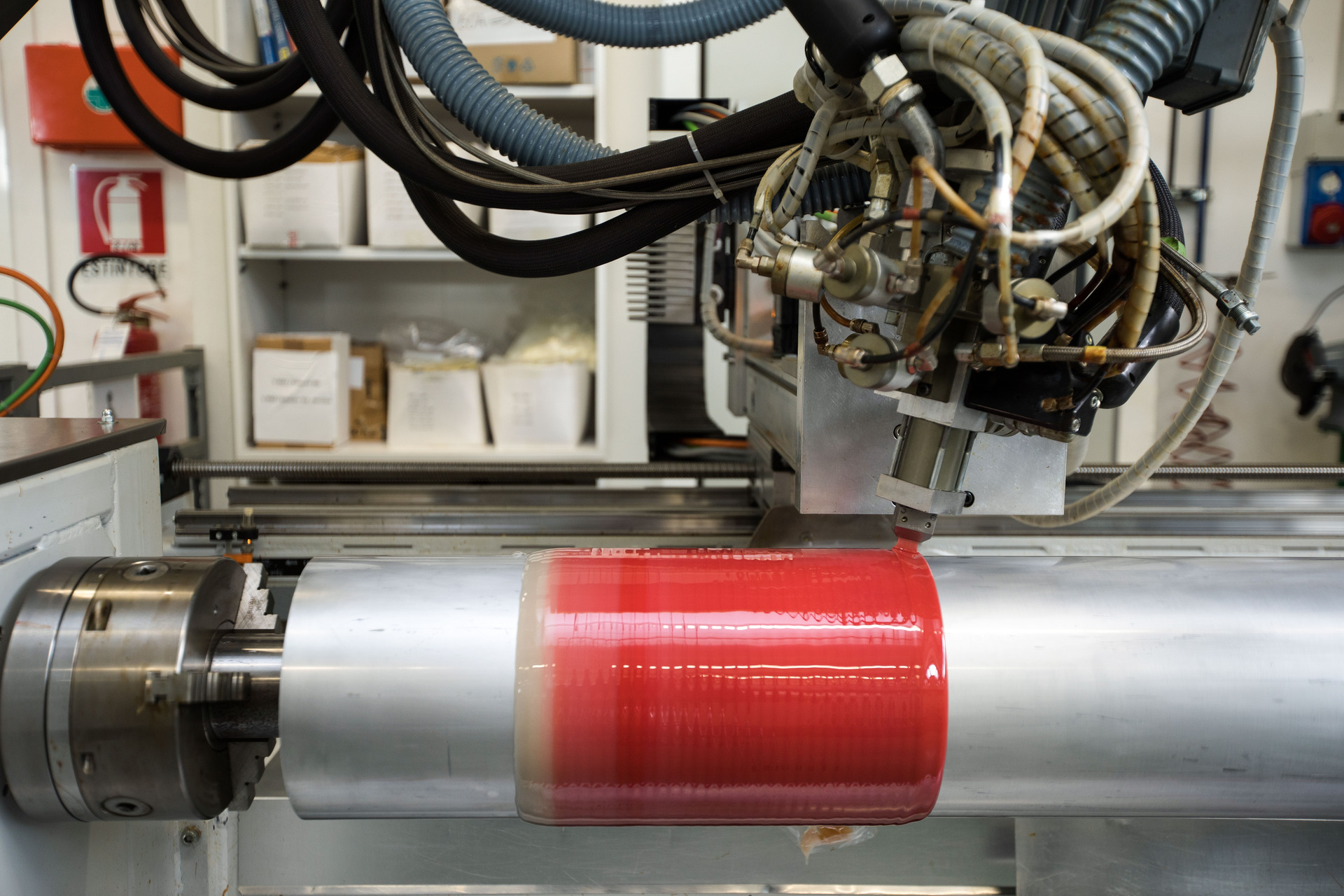

Adiprene® Ribbon Flow® systems are highly reactive and designed for use with a meter mix machine and a roll rotating mechanism to apply the urethane coating directly to the roll core (or other cylindrical object) without the need for a mold. The material cures on the rotating core as it is applied and the mix head of the meter mix machine slowly traverses the length of the core until the coating is complete. Adiprene® Ribbon Flow® prepolymers can be applied in coatings up to 40mm per pass and deliver tooling savings (no molds), reduced waste, improved productivity and lower production cost than conventional casting.

Adiprene® Ribbon Flow® rotational cast urethane prepolymers are available in both conventional and LF (low free), in single pass, multiple pass, 2K and 3K systems with various chemistries. LANXESS scientists can work with you to customize a special formulation to achieve your ideal performance.

Contact us now using the contact form on the bottom of the page.